Predictive/Preventive Maintenance System

IOT enabled Condition Monitoring System

IOT enabled Condition Monitoring System

INTRODUCTION

The process of monitoring the parameter of machinery (vibration, temperature etc.), in order to identify a significant change which is indicative of a developing fault. The use of condition monitoring allows for scheduled maintenance to take & prevent consequential damages and avoid its consequences .

The data collected can be used to establish trends, predict failure, and calculate remaining life of an asset. This new achievement in vibration monitoring technology is an ideal complement to traditional vibration analysis. The method is capable of detecting at a very early stage such machine problems which are generally difficult to identify early with conventional vibration monitoring techniques, such as gear and bearing damages.

Goal of CBM

The main goal of condition based maintenance is to help you optimize your maintenance resources by performing maintenance work only when needed. CBM makes use of the Predictive maintenance tools to detect, monitor, analyze and detect anomalies in machines.

Measurement Method

There are two types of vibration measurement methods "Permanent online vibration monitoring system" and "Portable off-line monitoring system". Either one is selected generally depending on importance rank of equipment.

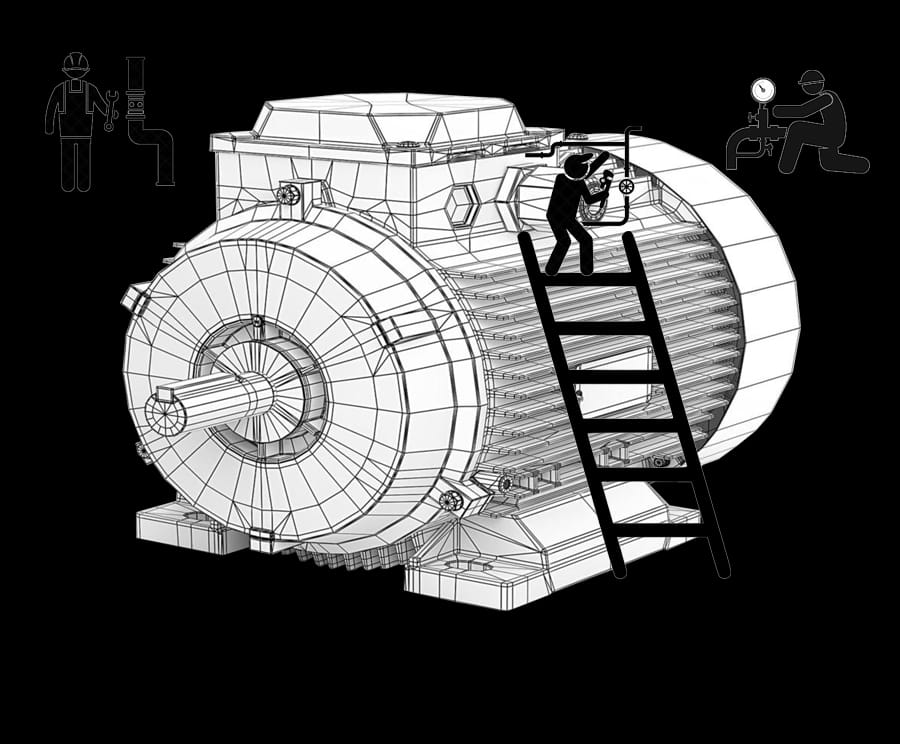

1. Online Monitoring :

Machinery that : is important

- Operates Constantly

- Cannot be Approached

- Deteriorates Slowly

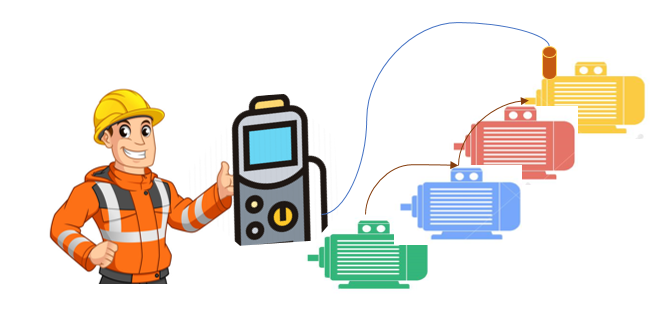

2. Offline Monitoring

Machinery that : is important

- Is Minimal impact from Breakdown

- Is Easy to be Measured

- Deteriorates Quickly

Our Solutions

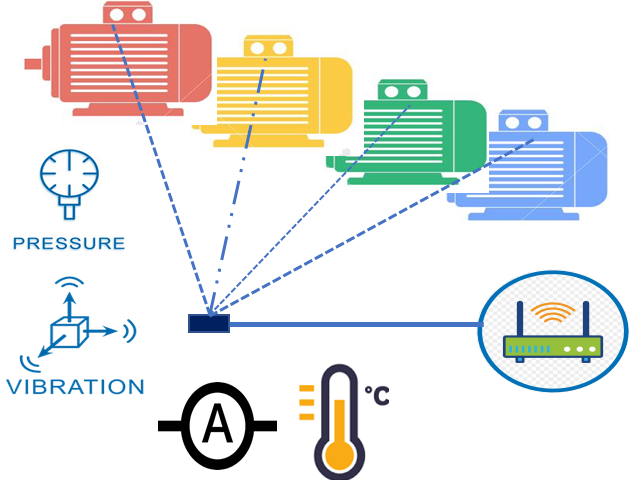

Stand Alone Compact CBM System

Features

- Compact size : 84mm*58mm*30mm in dimension

- Power supply : 5Vdc (Mobile Charger will do)

- Wi-Fi Connectivity : 3.5 -4 Mbps speed

- API can be shared

- Data on cloud (AWS Cloud)

- Magnet mounting, Stud Mounting easily

- Firmware upgradation over the Air

- No extra software requirement

- Mobile app and dashboard functionality

- Installations up to 3000+ installations

- No wiring or programming required

- Easy Installation with “FEW“ minutes

- FFT Functionality

- Report and Alarms

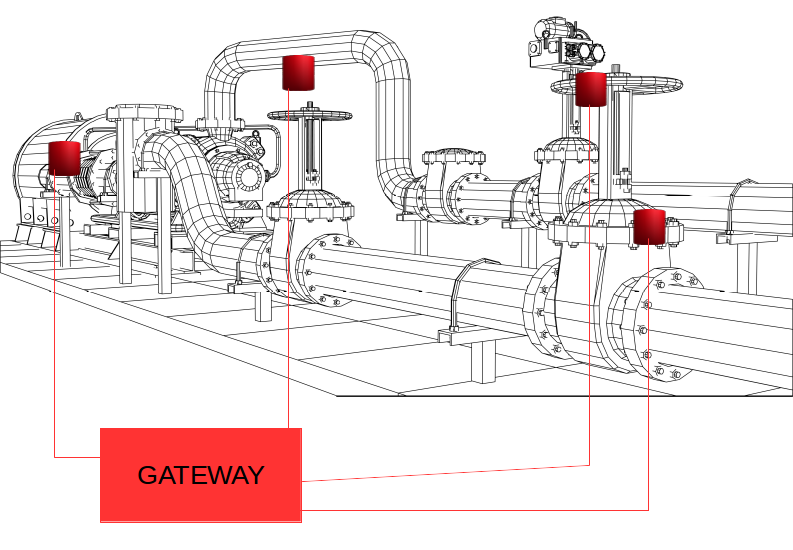

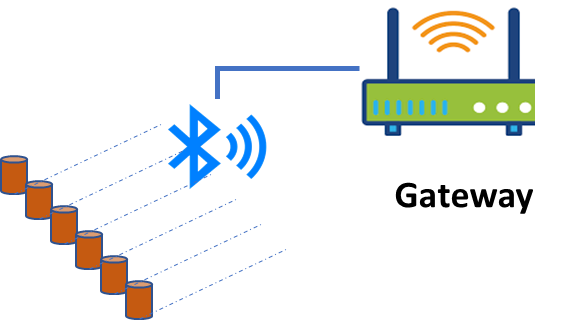

Gateway Based CBM Solutions

Features

- This solution will interact with gateway via Bluetooth technology

- Power supply : Battery operated

- Gateway Interface : Ethernet

- Can be interfaced up to sensor 256 nodes

- API can be shared

- Data on cloud and on premises solution

- Stud Mounting easily

- Firmware upgradation over the Air

- Packaged solution with software hardware

- Mobile app and dashboard functionality

- Waterfall analysis ,Machine downtime etc

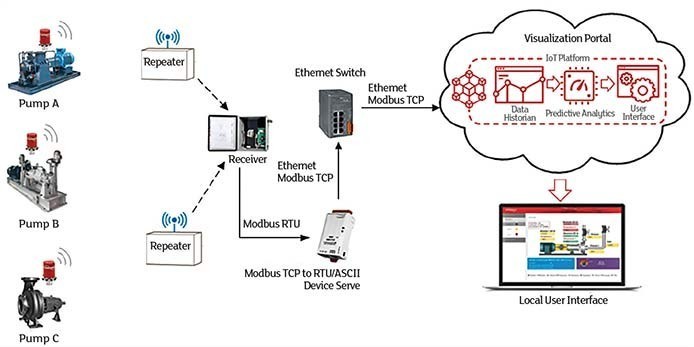

Controller Based CBM Solution

Features

- This solution consists of probe types sensors as per customised requirements

- Cabled sensors can be extended as per requirement

- This solutions is available for High temperature and vibration level requirements

- This solutions addresses all reciprocating application needs

- Needs dedication online/offline software

- Hardware controller and accessories

Applications

- Rotating Machines

- Reciprocating Machines

- Underwater Submersible Pumps

- CNC

- VNC

- Conveyor Systems

- Heat Exchangers

- Boilers

- Rolling Mill

- Spindle Motor

- Pumps

- Motors

- Gearbox

- ID & FD FANS